Combined Roller Bearings

In the world of industrial machinery and material handling systems, combined roller bearings play a vital role. These bearings are engineered to handle both radial and axial loads, making them a versatile choice for applications that involve linear motion and heavy-duty mechanical operations.

In this blog post, we will explore what combined roller bearings are, how they work, their advantages, typical applications, and how to choose the right one for your needs.

What is a

Combined Roller Bearing?

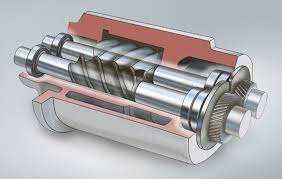

A combined roller bearing is a mechanical component that merges two types of rollers in one assembly: a radial roller (to support loads perpendicular to the shaft) and an axial roller (to support loads along the shaft).

This dual-function capability allows the bearing to effectively support loads in both directions, which is essential in guide systems and lifting equipment such as:

- Forklifts

- Vertical mast systems

- Conveyors

- Telescopic lifting columns

How Does a Combined Roller Bearing Work?

The structure of a combined roller bearing usually includes:

- Main radial bearing: Carries the main radial load (e.g., from weight or rotation)

- Lateral axial roller: Mounted on the side to manage thrust or axial loads

- Mounting flange or bolt hole: For secure installation in housing or frames

When in use, the radial roller carries the vertical load, while the axial roller guides motion along a rail or mast, reducing friction and preventing misalignment.

Benefits of Using Combined Roller Bearings

Here are some key advantages:

✅ Dual Load Capacity

They handle both radial and axial forces simultaneously, which saves space and simplifies design.

✅ High Load Rating

Combined bearings are suitable for heavy-duty applications due to their robust construction.

✅ Compact Design

By combining two bearings into one unit, you reduce space and weight in your machinery layout.

✅ Easy Installation

Most models come with pre-machined bolt holes or mounting studs, simplifying installation and maintenance.

✅ Long Service Life

With proper lubrication and minimal friction, these bearings last longer than standard roller assemblies.

Typical Applications

Combined roller bearings are widely used across industries where linear guidance and load support are essential. Common application areas include:

- Material Handling: Lift trucks, stackers, and conveyor systems

- Construction Equipment: Boom lifts, hoists, and mobile cranes

- Automation & Robotics: Guiding arms, rails, and precision sliders

- Warehouse Systems: Storage rack movement and telescopic mechanisms

- Rail Systems: Sliding door mechanisms, guide tracks, and heavy-duty gates

Types of Combined Roller Bearings

There are several variations of combined bearings, each designed for specific use cases:

- Stud-Type Combined Bearings

Mounted via a central stud bolt; commonly used in guided mast systems. - Yoke-Type Combined Bearings

Designed for shaft mounting; suitable for high-load applications. - Adjustable Combined Bearings

Feature eccentric bushings that allow fine adjustment to reduce play and ensure tight rail guidance. - Weld-On Versions

Can be welded directly to structural frames for heavy-duty, permanent installations.

Choosing the Right Combined Roller Bearing

When selecting a combined roller bearing, consider the following factors:

✔ Load Ratings

Know the radial and axial loads your system will exert and choose a bearing rated above those levels.

✔ Rail or Track Type

Check if your bearing needs to fit on an I-beam, C-rail, or custom profile.

✔ Environment

For outdoor or corrosive environments, choose sealed or stainless-steel bearings.

✔ Mounting Method

Decide whether a stud-type, yoke-type, or weld-on bearing is best for your frame structure.

✔ Speed and Frequency of Use

If your system moves continuously or rapidly, select bearings designed for high-speed operation with enhanced lubrication systems.

Maintenance Tips

To get the most out of your combined roller bearings:

- Regular Lubrication: Use proper grease or oil to avoid wear and tear.

- Check Alignment: Misaligned tracks or rails can reduce lifespan.

- Inspect Frequently: Watch for signs of pitting, wear, or noise.

- Protect from Contamination: Use sealed versions in dusty or wet environments.

Popular Brands Offering Combined Roller Bearings

Some well-known manufacturers include:

- McGill

- INA (Schaeffler Group)

- THK

- Rollon

- Nadella

- Ewellix (formerly SKF Motion Technologies)

Each brand may offer specialized series tailored to unique rail systems or industrial demands.

Final Thoughts

Combined roller bearings are a smart choice for engineers and maintenance professionals working with heavy-duty linear systems. Their ability to support dual-direction loads makes them invaluable in compact, high-load applications. Whether you’re designing a forklift mast or an automated conveyor rail, choosing the right combined bearing can improve performance, extend equipment life, and ensure smooth operation.

FAQs on Combined Roller Bearings

Q1: Can combined roller bearings be used in vertical applications?

Yes, they are ideal for vertical guidance systems, especially in lifting masts or elevators.

Q2: How long do combined roller bearings last?

With proper lubrication and load alignment, they can last thousands of hours, depending on use.

Q3: Are these bearings reusable after disassembly?

If not damaged or excessively worn, yes. Always inspect them thoroughly before reuse.

Q4: Do I need a separate track for axial rollers?

Yes, axial rollers typically run on a side rail or guiding flange.

Q5: Can I adjust play or tolerance in the bearing setup?

Adjustable versions allow fine-tuning via eccentric cams or bushings.